“… imagine a future in which energy will be distributed all over the world using only sustainable, light and economical materials …”

Products

Our products are made using aluminum as the main element, depending on the processing the finished product will then be used for different purposes.

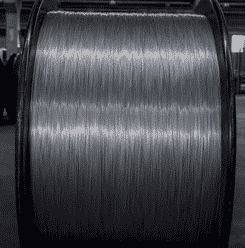

Flexible Conductor

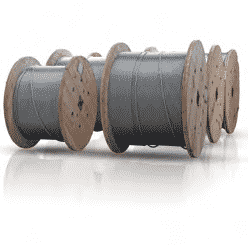

Rigid Conductor

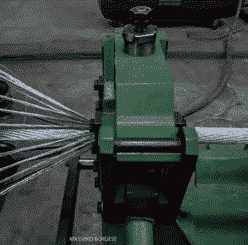

Heat Treatments

The production process includes heat treatments to restore the electromechanical properties of the wire rod or to achieve better performance in terms of flexibility, conductivity and concentricity. The heat treatments may also be necessary when special alloys of aluminum having a high breaking load and low elongation need to be drawn (up to capillary diameters). Based on final application and aging, heat treatments can be static or in line.

Property

Here are some of the advantages of using aluminum as a raw material.

Conductive not sparks

The specific electrical conductivity of aluminum makes it indispensable for electronics and electrical applications. Aluminum cables conduct electricity twice as much as copper with the same weight. The high thermal conductivity makes aluminum very suitable for heating and cooling applications. Unlike ferrous metals, aluminum does not generate sparks when it is rubbed with other metals.

Recyclable and Economical

Aluminum is easily recyclable with an energy cost equal to one twentieth of that necessary for its first fusion: almost a third of the aluminum consumed today is produced by recycling scrap, costs much less than copper, less than a third with peaks up to a fifth.

Malleable and Durable

Aluminum can be molded, with all common processing techniques and quickly develops an impenetrable oxide film on exposed surfaces, it is extremely resistant to atmospheric corrosion even in marine environments.

Lightweight and Versatile

With the same volume, aluminum weighs only a third of the steel, Aluminum alloys can be stiff or elastic, particularly robust or resistant to corrosion.